OUR HISTORY

since 1940

Meleuzovsky milk powder plant was put into trial operation. In the first year of its operation, 11,863 tons of milk were processed and 20 types of products were produced.

in 1950-х

The team, without expanding the area, began a radical technical re-equipment of the main and auxiliary shops, as well as the raw material zone of the enterprise.

in 1964

In order to enlarge production and improve public services, in 1964 the cannery was reconstructed at the plant with the installation of two additional drying plants and three vacuum / apparatus, which doubled the plant's capacity.

in 1966

The plant was renamed into "Meleuzovsky Milk Canning Plant".

since 1970-1975

Organizational and technical measures were taken at the enterprise: a whole-milk shop was equipped, an oil section was equipped with new equipment, a refrigerator with a capacity of 100 tons was built, a warehouse for finished products was built.

in 1992

In the course of privatization, the plant became a closed joint stock company. In 1993, according to the reconstruction plan, a skimmed milk powder shop with a drive-through and receiving department was put into operation.

in 1996

the bottling shop was reconstructed, instead of the bottling line, Nimco, Zond-Pak, Tetra-Brik automatic machines were installed, which pack milk in paper bags such as Tetra-Brik, Pure-Pak, plastic bags, which allowed for the same production areas to increase the capacity of the workshop. Sour cream, cream, yogurt, fermented baked milk are packaged in polystyrene cups.

in 2000

A course was taken for the intensification of production, technical and technological re-equipment, the creation of optimal conditions for partnership and cooperation with suppliers. The introduction of the packaging machine of the Dutch company BTH VLP-250-B made it possible to pack dry dairy products in accordance with European standards and norms.

since 2010-2014

In the canning shop, the food intake unit, showers, toilets were reconstructed, and a sanitary checkpoint was put into operation that meets food safety standards. A hygiene station has been installed with an effective system for drying and disinfecting shoes, a hand disinfection module with an automatic turnstile. Also, an automatic filling machine into bags TF-2 "Pit-Pak" was put into operation for packaging fermented milk products (kefir, fermented baked milk, katyk, bifilend). At the packing area for dry dairy products, the installation of self-leveling floors was completed; a high-pressure washing station was installed at the milk intake, which provides high-quality washing and disinfection of tankers. The homogenization site was overhauled with the installation of Italian-made Bertoli homogenizers. The food safety management system implemented at the plant is certified in accordance with international requirements FSSC 22000.

since 2015-2017

The plant was awarded the Grand Prix for cream powder in the competition "Dairy Success", the prize "Taste of Quality" in the framework of the All-Russian Program "100 Best Goods of Russia" for high achievements in the field of quality and food safety, a gold medal for dry dairy products at the exhibition " Agrocomplex”, diploma of the laureate for butter “Krestyanskoye” in the competition “Best Goods of Bashkortostan”.

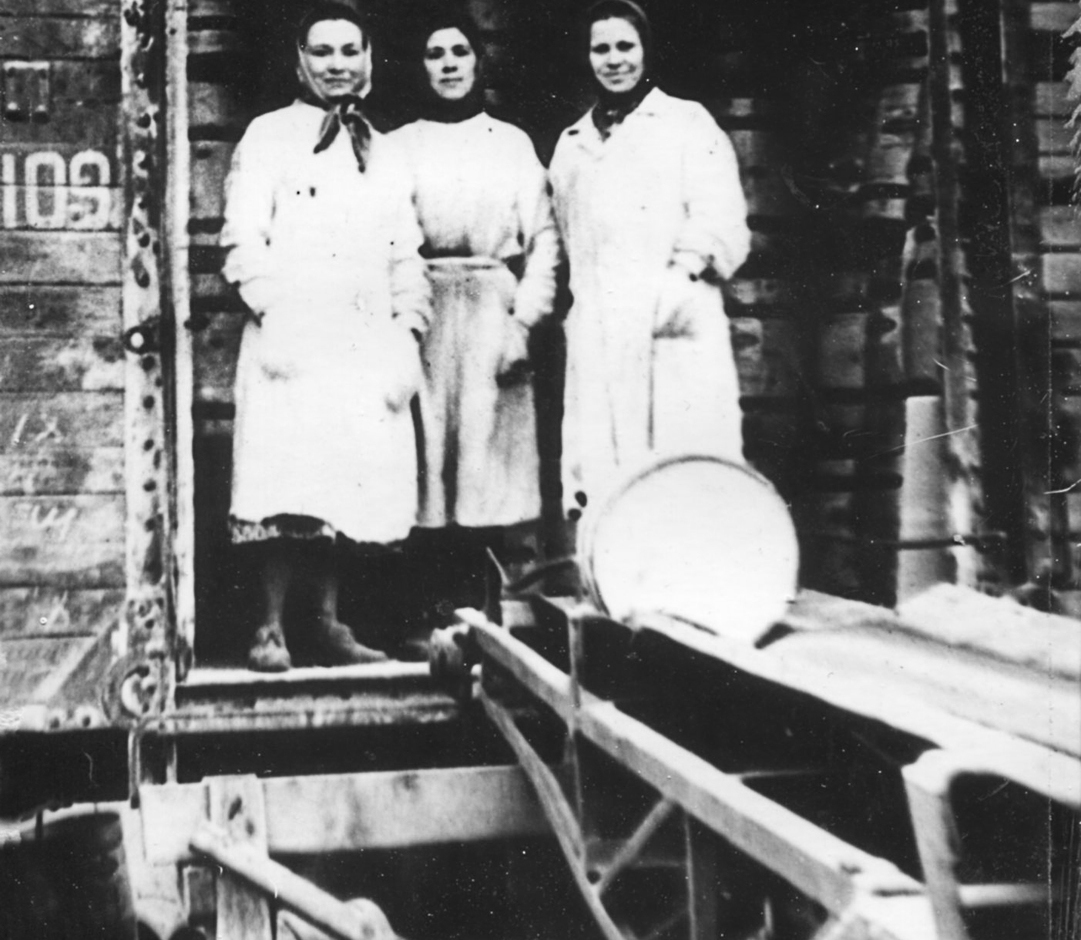

Production photos